MC SERIES

BASE® continuous mixer MC series is realized with an external structure in standard steel internally covered with replaceable parts made of heat treated anti-wear steel. The product is mixed by using of 2 parallel axes equipped with welded arms and bolted blades made of Ni-Hard cast iron. The movement of the mixing parts is ensured by one or more electric motors combined with reducers and torque dividers acting on the two shafts.

The BASE® continuous mixers MC series find their most usual use in plants for the production of hydraulically mixed concrete, in very rare cases they can also be used for the production of low performance concrete, for example, for the preparation of cement mixes and lean concrete for roads and airports and for the production of mortars. The MC series mixers ensure very high hourly production rates and low energy consumption.

- Low maintenance costs

- Reliability over time

MIXING BLADES

The counter-rotation of the two shafts with a large number of blades generates intense turbulence, especially in the overlapping area. The vertical and horizontal movement creates a very fine disintegration of the cement in the aggregates (introduced in the right proportions). Blades are made of anti-wear fusion.

INSPECTION DOORS

Cover with four inspection doors and two inspection hatches, with protection net. Safety devices according to accident prevention regulations.

| Technical data | MC | 100 | 150 |

|---|---|---|---|

| Output (fresh concrete) | m³/h | 100 | 150 |

| Workable grain size | mm | 70 | 70 |

| Mixer drive | kw | 18 | 22 |

| Mixing paddles | nr. | 40 | 40 |

| Weight | kg | 2800 | 2900 |

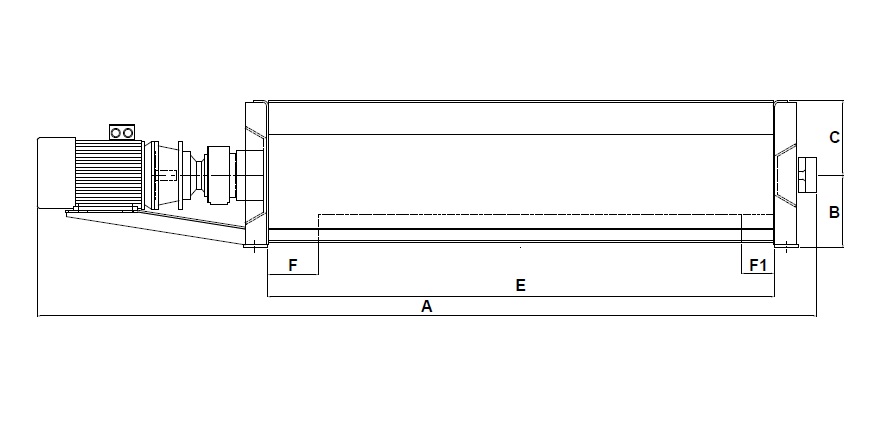

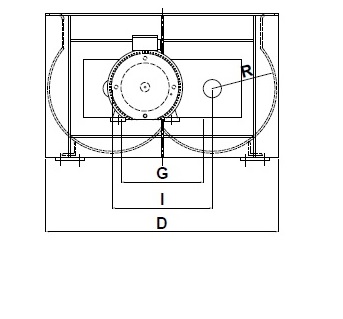

| MC SERIES | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Dimensions | |||||||||

| Code | A | B | C | D | E | F (F1) | G | I | R |

| BSMC100 | 4040 | 375 | 390 | 1206 | 2600 | 250 | 500 | 520 | 315 |

| BSMC150: | 4040 | 375 | 390 | 1206 | 2600 | 250 | 500 | 520 | 315 |

F: standard discharge

F1:: alternative discharge

Drawings, technical data and dimensions subject to change without notice.