Vibrating fluidifiers, fluidification nozzles and pads to improve the descent of material inside hoppers or silos in a concrete mixing plant.

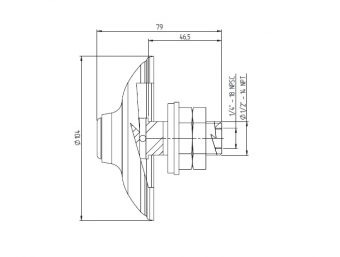

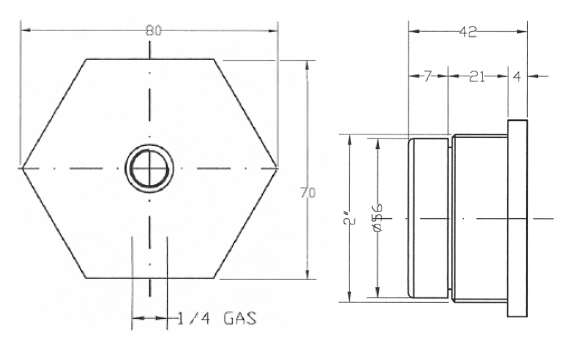

FLUIDIFICATION NOZZLES

BASE® fluidizing nozzles are made of polystyrene (PS) plastic with a 2″ gas thread for mounting on the supplied metal sleeve and a ¼” gas thread for mounting on the air connection. The air blowing surface is made of synthetic polyethylene (PE) material.

Fluidization nozzles are usually mounted on the outside of the silo cone and can be easily replaced without emptying the silo. Since they can work at a much higher air pressure than conventional fluidization plates, they guarantee a high disintegration capacity of the product, favouring its descent towards the discharge outlet. Depending on the size of the silo, from 4 to 12 units can be installed.

- Ease of installation

- Low maintenance costs

- Compact product dimensions

- Versatility of use

| Code | Descrption |

|---|---|

| BSUF50 | Fluidization nozzle |

| Technical Details | |

| Working pressure | 0.5 ÷ 3 bar |

| Air consumption | 0.75 Nm³/h a 2 bar |

| Unit weight | 0.3 Kg |

| Body material | Polystyrene (P.S.) |

| Disc material | Polyethylene (P.E.) |

| Connection | 1/4 “ GAS |

VIBRATING FLUIDIFIERS

The vibrating fluidifier is made of a stainless steel body internally threaded by ¼” gas for the air connection, and externally threaded by ½” gas complete with nuts and gaskets for mounting on the silo, and a white silicone membrane.

BASE® vibro-fluidifiers are mounted inside the silo. The silicone membrane generates vibrations when air is blown through the silo, which allows the product to be disintegrated more efficiently than with conventional fluidizers and allows it to flow down to the discharge outlet. Depending on the size of the silo, 4 to 12 units can be installed. In order to replace it, the silo must be empty to intervene from the inside.

- Ease of installation

- Product of compact dimensions

| Part no. | Description |

|---|---|

| BSVBSI | stainless steel vibro-fluidifier DN100 with white silicone membrane |

| AIR CONSUMPTION | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 0.8 bar | 1.2 bar | 2 bar | 4 bar | 6 bar | |||||

| L/min | Cfm | L/min | Cfm | L/min | Cfm | L/min | Cfm | L/min | Cfm |

| 600 | 21.1 | 675 | 23.8 | 800 | 28.2 | 950 | 33.5 | 1150 | 40.6 |

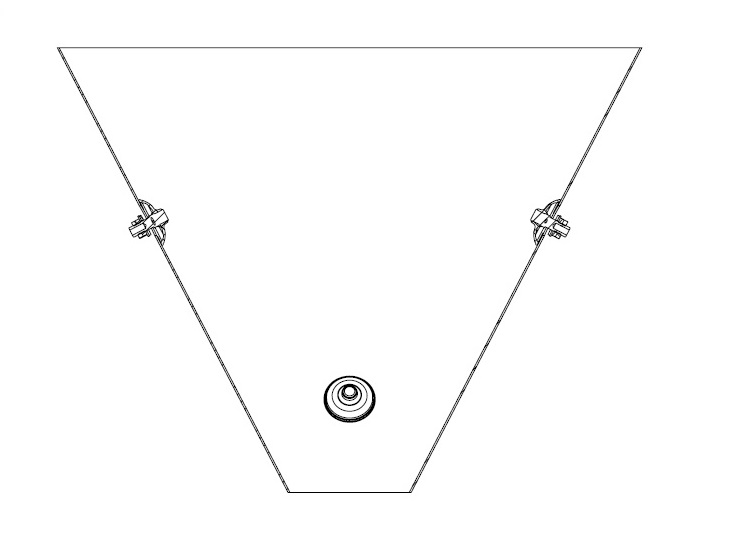

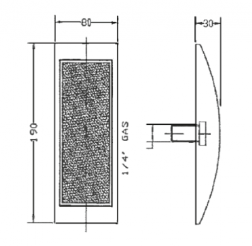

FLUIDIFIZATION PADS

Fluidization plates are made of polystyrene (PS) plastic material with a ¼” gas thread for the air connection which also serves as a fastening system to the silo wall. The large air blowing surface is made of polyethylene (PE) synthetic material.

Fluidizing plates, a historical product on the market, to be mounted inside the silo. They have a good suffrage surface that guarantees an excellent disintegration of the product inside the silo already at low pressures. In order to replace it, the silo must be empty to intervene from the inside.Depending on the size of the silo, 4 to 12 units can be installed.

- Ease of installation

- Product of compact dimensions

| Code | Description |

|---|---|

| BS100.011 | Fluidization pad |

| Technical details | |

| Working pressure | 0.4 ÷ 0.8 bar |

| Air consumption | 0.6 ÷ 1 Nm³/h a 0.5 bar |

| Unit weight | 0.5 Kg |

| Body material | Polystyrene (P.S.) |

| Disc material | Polyethylene (P.E.) |

| Connection | 1/4 “ GAS |

| Adapter | 1/4 “ GAS – 3/4 “ GAS |