Rollers for conveyor belts for quarries and concrete plants. For greater resistance to external conditions, all rollers are manufactured with stamped and calibrated sheet metal heads, welded to the hot-rolled steel shell with a thickness of ≥ 3mm. Precision ball bearings with permanent lubrication are always mounted, protected on the outside by double or triple labyrinth seals and on the inside by a lip seal that prevents grease leakage.

At the end of the production process, each roller is tested on a machine that keeps it rotating for the time necessary for the uniform distribution of the lubricant.

We can provide different types of rollers, according to our customers’ needs:

- idler rollers, for light or extra heavy loadings

- rubber coated impact rollers, spacers, cleaning helical rollers made of rubber or steel

- guide rollers and 2-rollers projecting units

- drum motor rollers

- drive drums and transmission drums

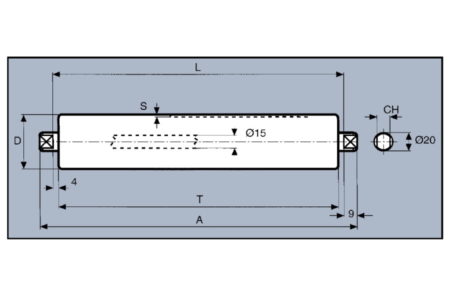

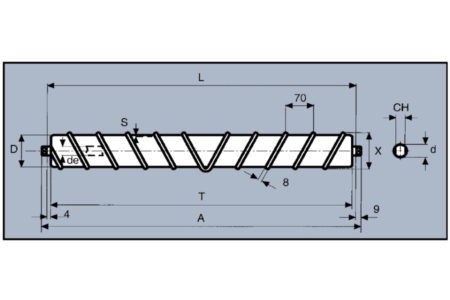

Steel idle rollers with watertight double labyrinth sealing assembled on first rate precision 6202 ball bearings with continuous lubrication. Tube with constant thickness and heads connected through soldering. The rollers are used on medium load belt conveyors moving at high speeds even in poor environmental conditions.

| D | S | L | T | A | CH | Peso L=200 mm | Kg/cm |

|---|---|---|---|---|---|---|---|

| 38 | 3 | T+8 | L -8 | L+18 | 17 | 0.92 | 0.04 |

| 50 | 3 | T+8 | L -8 | L+18 | 17 | 1.31 | 0.05 |

| 60 | 3 | T+8 | L -8 | L+18 | 17 | 1.38 | 0.06 |

| 76 | 3 | T+8 | L -8 | L+18 | 17 | 1.73 | 0.07 |

| 80 | 3 | T+8 | L -8 | L+18 | 17 | 1.85 | 0.08 |

| 89 | 3 | T+8 | L -8 | L+18 | 17 | 2.05 | 0.09 |

| 102 | 3.5 | T+8 | L -8 | L+18 | 17 | 2.45 | 0.10 |

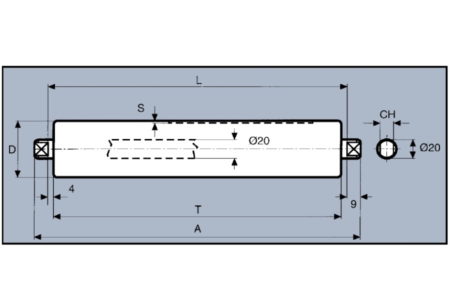

Steel idle rollers with watertight triple labyrinth sealing assembled on first rate precision 6204 ball bearings with continuous lubrication. Tube with constant thickness and heads connected through soldering. The rollers are used on heavy load belt conveyors moving at high speeds even in poor environmental conditions.

| D | S | L | T | A | CH | Peso L=200 mm | Kg/cm |

|---|---|---|---|---|---|---|---|

| 60 | 3 | T+8 | L -8 | L+18 | 14/17 | 1.82 | 0.07 |

| 76 | 3 | T+8 | L -8 | L+18 | 14/17 | 2.21 | 0.08 |

| 80 | 3 | T+8 | L -8 | L+18 | 14/17 | 2.37 | 0.08 |

| 89 | 3 | T+8 | L -8 | L+18 | 14/17 | 2.54 | 0.09 |

| 102 | 3.5 | T+8 | L -8 | L+18 | 14/17 | 2.88 | 0.11 |

| 108 | 3.5 | T+8 | L -8 | L+18 | 14/17 | 2.97 | 0.12 |

| 133 | 5.5 | T+8 | L -8 | L+18 | 14/17 | 3.90 | 0.16 |

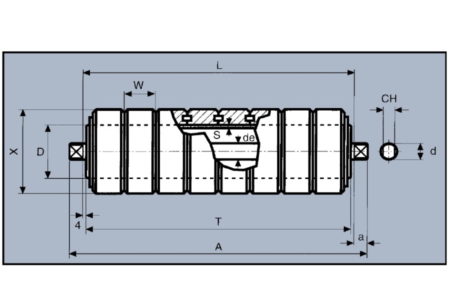

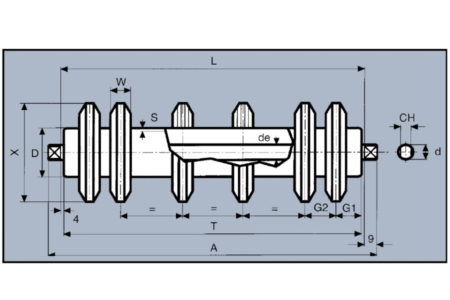

The impact rollers consist of a base roller on which a set of rubber anti-abrasion rings in installed. These are used to reduce the impact of falling material in order to prevent belt damage.

The impact rollers consist of a base roller on which a set of rubber anti-abrasion rings in installed. These are used to reduce the impact of falling material in order to prevent belt damage.

| D | X | S | L | T | A | W | de | a | d | CH | Tipo Anello | Peso |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 60 | 89 | 3 | T+8 | L -8 | L+8 | 30 | 15 | 9 | 20 | 17 | A10 | 0.10 |

| 60 | 102 | 3 | T+8 | L -8 | L+8 | 30 | 15 | 9 | 20 | 17 | A11 | 0.17 |

| 60 | 108 | 3 | T+8 | L -8 | L+8 | 30 | 15 | 9 | 20 | 17 | A12 | 0.20 |

| 60 | 89 | 3 | T+8 | L -8 | L+8 | 30 | 20 | 9 | 20 | 14/17 | A10 | 0.10 |

| 60 | 102 | 3 | T+8 | L -8 | L+8 | 30 | 20 | 9 | 20 | 14/17 | A11 | 0.17 |

| 60 | 108 | 3 | T+8 | L -8 | L+8 | 30 | 20 | 9 | 20 | 14/17 | A12 | 0.20 |

| 89 | 133 | 3 | T+8 | L -8 | L+8 | 30 | 20 | 9 | 20 | 14/17 | A13 | 0.22 |

| 89 | 159 | 3 | T+8 | L -8 | L+8 | 45 | 20 | 9 | 20 | 14/17 | A14 | 0.48 |

| 89 | 133 | 3 | T+8 | L -8 | L+24 | 30 | 25 | 12 | 25 | 17/18 | A13 | 0.22 |

| 89 | 159 | 3 | T+8 | L -8 | L+24 | 45 | 25 | 12 | 25 | 17/18 | A14 | 0.48 |

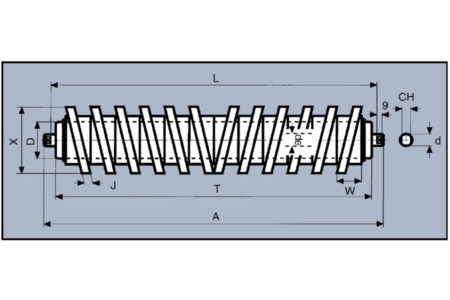

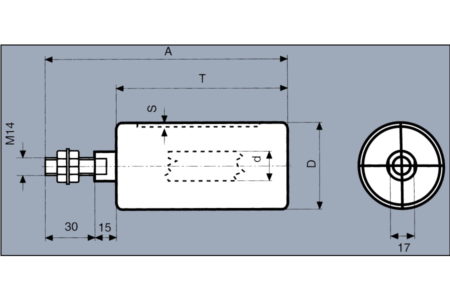

The cleaning rollers with helical ring, made of anti-abrasion rubber, are fitted into a base roll from the centre to the right and left, in order to eject material to the sides of the belt.

| D | L | T | A | X | W | J | de | CH | d | Peso Anello |

|---|---|---|---|---|---|---|---|---|---|---|

| 60 | T+8 | L -8 | L +18 | 108 | 45 | 11 | 15 | 17 | 20 | 0.17 |

| 60 | T+8 | L -8 | L +18 | 108 | 45 | 11 | 20 | 14/17 | 20 | 0.17 |

The rollers with spaced anti-adhesion rings consist of a base roller and are used to sustain the belt on its return when used to transport sticky materials avoiding the build-up of crusty deposits which may affect the regular forward movement of the belt.

The rollers with spaced anti-adhesion rings consist of a base roller and are used to sustain the belt on its return when used to transport sticky materials avoiding the build-up of crusty deposits which may affect the regular forward movement of the belt.

| D | X | S | L | T | A | de | W | G1 | G2 | CH | d | Tipo Anello | Peso Anello |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 60 | 108 | 3 | T+8 | L -8 | L+8 | 15 | 22 | 100 | 50 | 17 | 20 | D20 | 0.12 |

| 60 | 133 | 3 | T+8 | L -8 | L+8 | 15 | 30 | 100 | 50 | 17 | 20 | D21 | 0.26 |

| 89 | 133 | 3 | T+8 | L -8 | L+8 | 15 | 30 | 100 | 50 | 17 | 20 | D22 | 0.21 |

| 60 | 108 | 3 | T+8 | L -8 | L+8 | 20 | 22 | 100 | 50 | 14/17 | 20 | D20 | 0.12 |

| 60 | 133 | 3 | T+8 | L -8 | L+8 | 20 | 30 | 100 | 50 | 14/17 | 20 | D21 | 0.26 |

| 89 | 133 | 3 | T+8 | L -8 | L+8 | 20 | 30 | 100 | 50 | 14/17 | 20 | D22 | 0.21 |

| Nastro | 400 | 450 | 500 | 600 | 650 | 700 | 800 | 1000 | 1200 | 1400 |

|---|---|---|---|---|---|---|---|---|---|---|

| L | 508 | 558 | 608 | 708 | 758 | 808 | 958 | 1158 | 1408 | 1608 |

| N | 5 | 5 | 6 | 6 | 6 | 7 | 7 | 9 | 10 | 11 |

The steel spiral clearing rollers are made of a base roller on which two steel spirals are welded from the centre to the right and left in order to eject material to the sides of the belt.

| D | S | L | T | A | CH | d | de | X | Peso Spirale al cm |

|---|---|---|---|---|---|---|---|---|---|

| 60 | 3 | T+8 | L -8 | L +8 | 17 | 20 | 15 | 76 | 0.010 |

| 76 | 3 | T+8 | L -8 | L +8 | 17 | 20 | 15 | 92 | 0.013 |

| 89 | 3 | T+8 | L -8 | L +8 | 17 | 20 | 15 | 105 | 0.016 |

| 60 | 3 | T+8 | L -8 | L +8 | 14/17 | 20 | 20 | 46 | 0.010 |

| 76 | 3 | T+8 | L -8 | L +8 | 14/17 | 20 | 20 | 62 | 0.013 |

| 89 | 3 | T+8 | L -8 | L +8 | 14/17 | 20 | 20 | 105 | 0.016 |

Customized rollers available on demand.

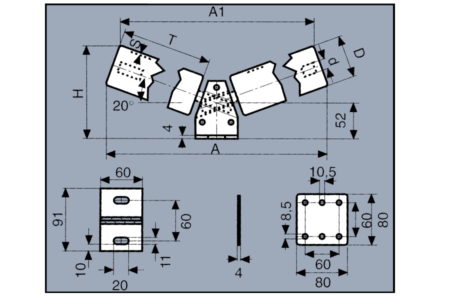

The couple of rollers are made from series P300 base rollers. The particularly innovative construction of central support enables separate replacement of the rollers, while the extremely tight placement allows for the use of very flexible belts.

| H | A | A1 | d | D | S | T | Peso | Nastro |

|---|---|---|---|---|---|---|---|---|

| 155 | 430 | 390 | 15 | 60 | 3 | 190 | 2.95 | 300 |

| 173 | 520 | 480 | 15 | 60 | 3 | 240 | 3.50 | 400 |

| 183 | 586 | 550 | 15 | 60 | 3 | 275 | 3.95 | 450 |

| 191 | 630 | 595 | 15 | 60 | 3 | 300 | 4.25 | 500 |

| 215 | 730 | 695 | 15 | 60 | 3 | 350 | 4.85 | 600 |

| 165 | 440 | 385 | 15 | 76 | 3 | 190 | 3.72 | 300 |

| 180 | 530 | 480 | 15 | 76 | 3 | 240 | 4.45 | 400 |

| 195 | 580 | 545 | 15 | 76 | 3 | 275 | 4.92 | 450 |

| 200 | 648 | 593 | 15 | 76 | 3 | 300 | 5.25 | 500 |

| 217 | 744 | 690 | 15 | 76 | 3 | 350 | 5.95 | 600 |

| 190 | 526 | 475 | 15 | 89 | 3 | 240 | 5.22 | 400 |

| 203 | 590 | 540 | 15 | 89 | 3 | 275 | 5.85 | 450 |

| 208 | 640 | 590 | 15 | 89 | 3 | 300 | 6.30 | 500 |

| 223 | 736 | 685 | 15 | 89 | 3 | 350 | 7.20 | 600 |