EXCELLENCE IN 3 DIVISIONS

RM® works in the construction industry, especially in the field of buildings and infrastructures. It has grown over the years and has consolidated itself by acquiring facilities that have allowed the expansion of the company, becoming an important and reliable reference in the production and supply of wear parts, accessories and equipment for concrete pumps and batching plants and machines for handling and processing aggregates. Established in 1986 in Ravenna, RM® currently covers an area of about 4.500 sqm used as offices, production facilities, warehouse and repair workshop. In 2000 it opened its doors abroad and today boasts more than 1200 customers in more than 70 countries spreading from Europe to the Middle East, from the United States to South America.

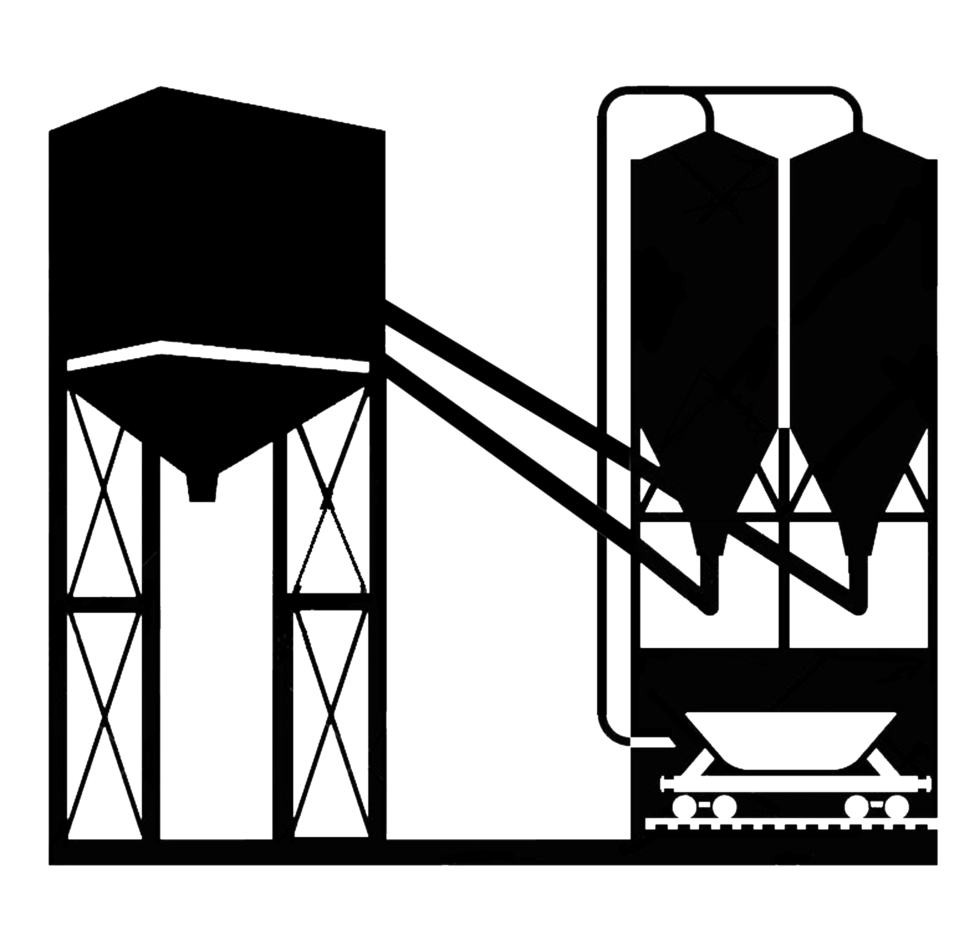

With the aim of offering an increasingly complete and advanced service, thanks to its three brands VEGA®, BASE® and EXTREME®, developed over the years, RM® offers a global service for those operating in the concrete and batching plants division as well as in the earthmoving industry.

MISSION

Establish ourselves as a leading company in the production and delivery of wear parts and accessories for various machines, used for mining, mixing and delivery of concrete and conglomerates. Be the customer’s landmark for quality and reliability of our products, as well as an excellence centre for repair and maintenance of machines for concrete delivery, construction machinery and special machines.

ISO 9001 Certification

On 31st Oct. 2019, we obtained the Certification of Conformity to the UNI EN ISO 9001:2015 law, regarding the Quality Management System. ISO 9001 is based on a series of principles about quality management, focusing strongly on the customer satisfaction through the application of internal procedures aimed at a continuous improvement. With this achievement, we want to enhance our company management system, in order to guarantee our best possible services for our employees, customers and partners. The Certificate was released by SGS, worldwide leading company for inspection, verification, analysis and certification.

QUALITY POLICY

RM® set the target of becoming a leading company in the production and distribution of wear parts for extracting, mining, transport equipment and conglomerate laying. The company wants to become a benchmark for customers in terms of quality and reliability of the products, and an excellence centre for repair and maintenance of concrete transport machines, equipment for the construction industry and special machines. In order to achieve the targets and maintain them in the future, the Company adopts a Quality Management System based on the UNI EN ISO 9001:2015 law. The Company Management System has been developed to obtain an effective and efficient use of resources in order to meet the expectations of customers and all the interested parties. To make this possible, this policy defines the following targets:

- to adopt and maintain a Quality Management System in the processes, products and services of the context in which the Company operates, respecting the legal requirements and procedures that the Company decides to adopt.

- define the responsibilities assigned to all company functions and verify their correct understanding and application.

- motivate and involve all personnel, ensuring the availability of the resources necessary to control all the processes, using training and education activities for employees to improve the skills and awareness of their role.

- define and spread clear information throughout documents, to ensure the effective and efficient functioning of the various processes.

- understand and meet the needs of customers and other stakeholders, through quality products and services meeting the expectations and a policy of continuous improvement.

- select and qualify suppliers, in order to maintain a strong and lasting partnership characterized by a constant reciprocity of intents.

- carry out internal audits to measure the effectiveness of the Quality Management System and adopt corrective actions to remove any causes of inadequacy.

- verify a correct management of resources (financial, structural, human) in order to guarantee a continuous growth of the Company and a remuneration of the resources committed by the Owner.

The General Management, with the help of the Quality Management System Manager, must adopt and spread the commitments and objectives listed above in order to achieve these objectives and the continuous improvement of the effectiveness of the System. This Quality Policy must be made available to all the internal and external stakeholders.