Lubas® branded polyurethane L-PUR® sieves and accessories

We always try to offer quality spare parts, aware that in our industry every minute counts and that the profitability of a plant depends on minimizing stoppages and downtimes.

The choice of highly wear resistant parts is just as crucial as the choice of the right partner, especially in an increasingly demanding market such as ours. For this reason, was born the collaboration with Lubas®, a leading Polish company in the production of polyurethane products and equipment.

Lubas® branded products are characterized by high durability and abrasion resistance combined with proper flexibility that avoids clogging, thanks to modern high-tech machinery and a team of experienced and qualified people.

The L-PUR® polyurethane compound, the result of years of research and development, is a hallmark of Lubas® sieves designed to withstand the toughest challenges.

Thanks to our partnership with Lubas®, we will have access to cutting-edge technology and innovations in the field of polyurethane, guaranteeing state-of-the-art products.

The installation of polyurethane panels in aggregates plants, such as those used in the production of concrete or asphalt, can offer several advantages:

- Know-how: the experience of RM® combined with the technological skills of Lubas® lead to the choice of the right polyurethane compounds and hardness, according to the type of operation and the material being screened, avoiding clogging and allowing maximum plant efficiency.

- Premium quality: Lubas® polyurethane sieves are renowned for their quality and durability, guaranteeing long-term reliable performances thanks to their unique patented L-PUR® compound.

- Wear Resistance: in addition to sieves designed to withstand wear, abrasion and mechanical stress, guaranteeing a long service life and reducing maintenance costs, Lubas® offers a wide range of coatings and panels for the protection of chutes, hoppers and all structural elements of plants.

- Customization: products can be customized according to specific requirements, type of application and material screened.

- Ease of installation: the lightness and flexibility of polyurethane panels highly simplify the installation process.

- Eco-Sustainability: polyurethane panels meet ecological standards, thus helping to reduce environmental impact.

The use of polyurethane panels in aggregate plants can help improve operational efficiency, equipment durability and the quality of the production process.

- Lightness: polyurethane is a lightweight material, which prevents adding excessive weight to the system

- Resistance: Lubas® polyurethanes are able to resist mould and fungus that form in the case of long-lasting stays

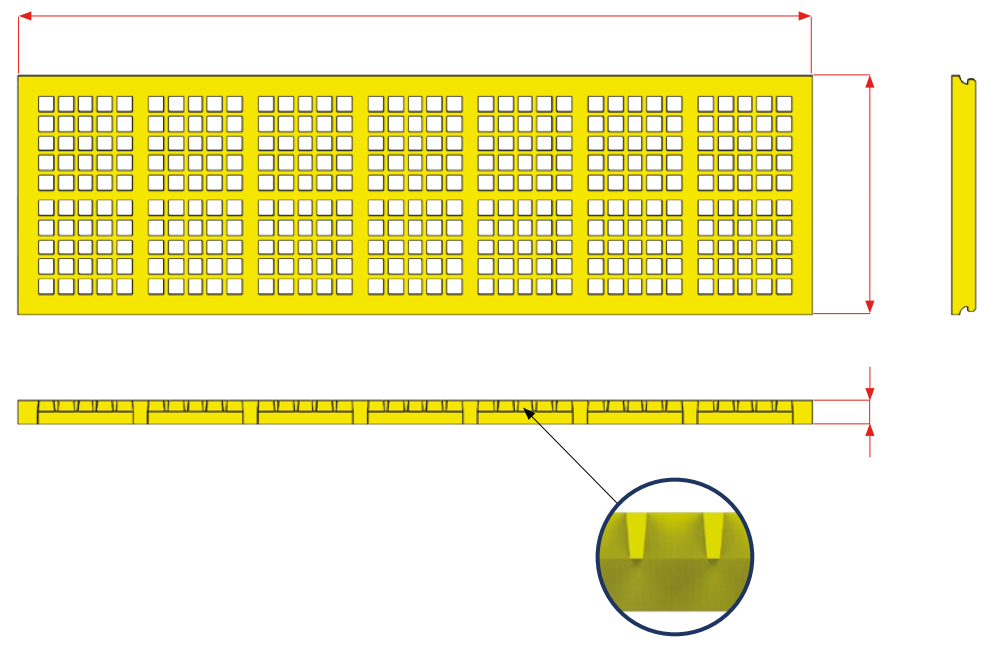

SEGMENT SIEVE MEASUREMENT

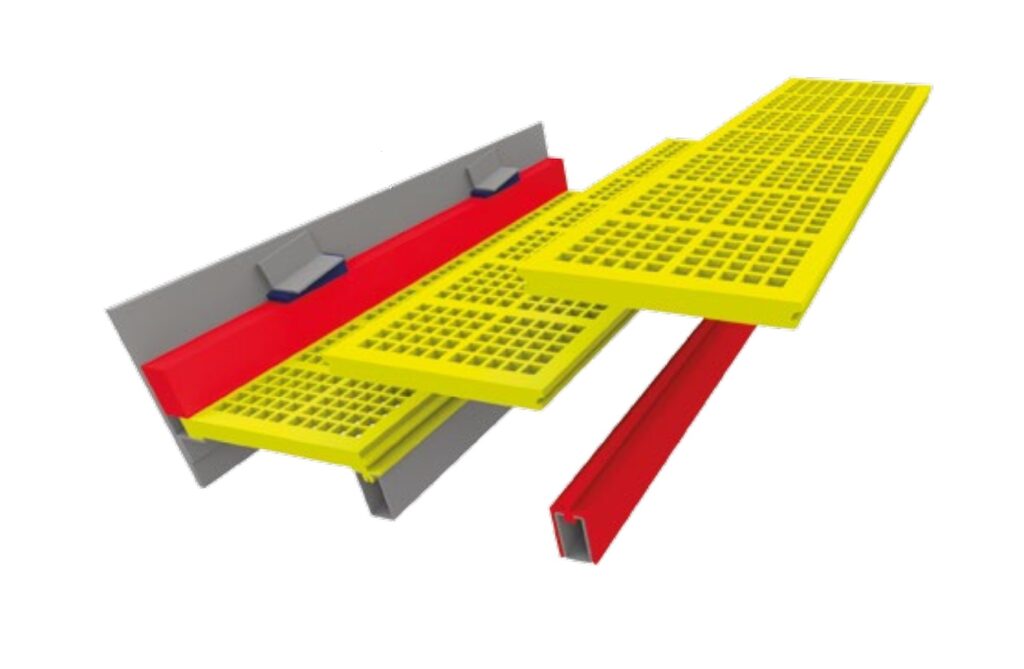

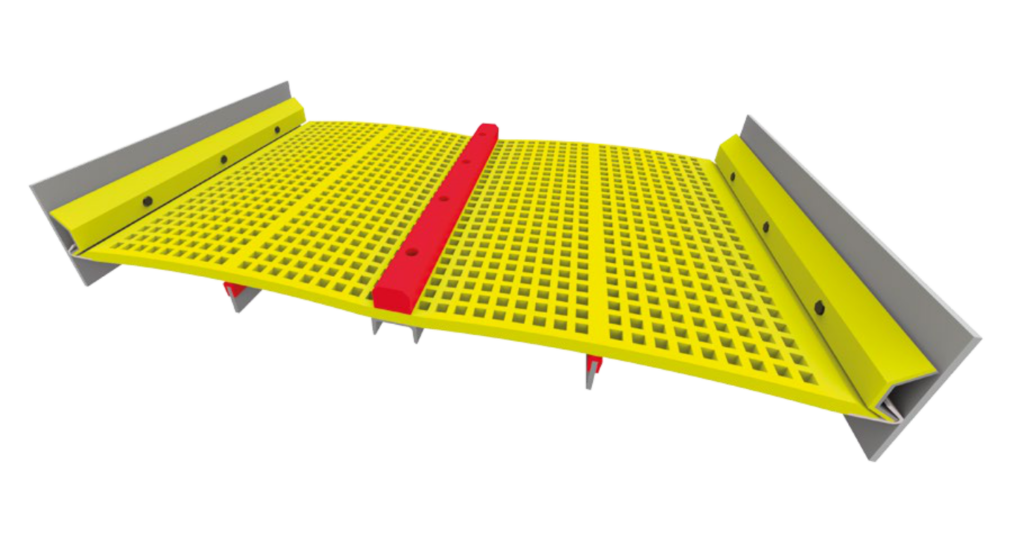

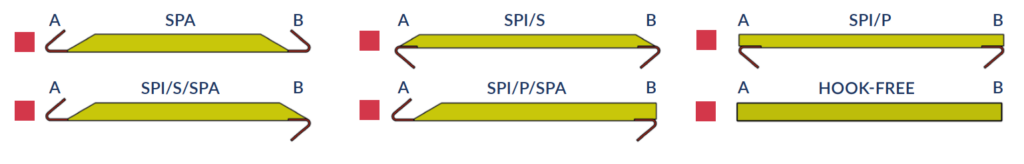

Screen types

- Transversally tensioned

- Longitudinally tensioned

- Self-supporting panel without hooks

- Modular panels for different systems

Sieve

- Sieve dimensions

- Number of levels

Material

- Type of aggregate

- Size

- Maximum capacity t/h

- Material form: crushed – natural

Hook types

Hook shapes

DATA SHEET

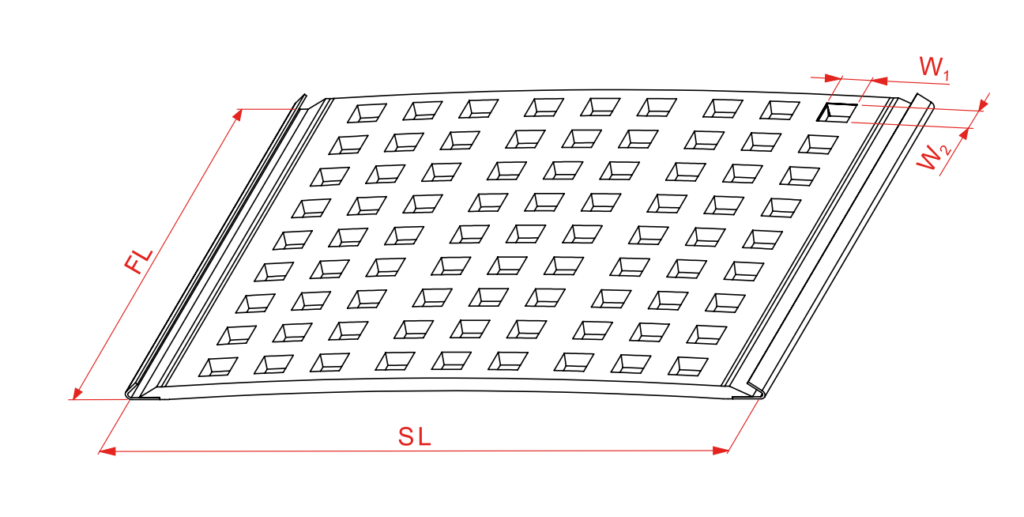

| TECHNICAL DATA | |

|---|---|

| Sieve length | SL |

| Hook lenght | FL |

| Mesh | W1 – W2 |

| Mesh spacing | REGULAR |

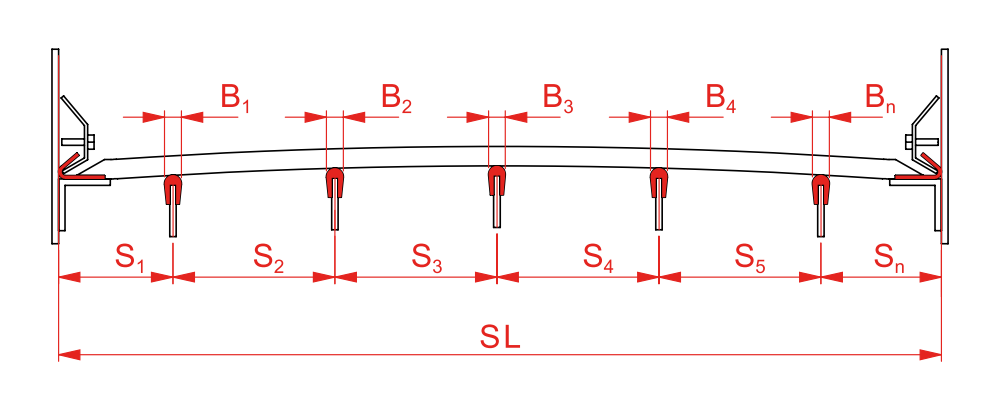

| TECHNICAL DATA | |

|---|---|

| Support spacing | S |

| Support spacing | B |

| Central bar* | if present provide drawing with dimensions and possible fastening systems |

| Sieve thickness | 30 mm – 40 mm – 50 mm – 60 mm |

| Sieve hardness | |

| Overlap* | specify the type |