Wear plates and rings

In the pumping unit of a machine, the most important function is represented by the exchange that occurs through the movement of the S-valve; the contact and the seal between the parts is maintained and guaranteed by the wear ring that moves on the relative wear plate. RM® produces wear plates and rings compatible with the main brands of concrete pumps in the market. These components can be made of heat-treated cast iron or steel with tungsten carbide coatings, with very high strength.

| Standard Wear Plate | Wear Plate with Carbid | Description | Standard Wear Ring | Wear Ring with Carbide | Wear Ring with Hard Carbide |

|---|---|---|---|---|---|

| – | 1401518 | wear plate DN 180 | - | 1031257 | - |

| 1401097TV | 1401097 | wear plate DN 200 | 1031104TV | 1031104 | 1031230 |

S-Valve

In the pumping unit of a machine, the S-valve has the most important function in the exchange phase for pumping concrete. RM® produces S-valves made of spheroidal cast iron which are highly resistant to torsion and abrasion. They are compatible with the main brands of concrete pumps in the market.

| Part Number | Description |

|---|---|

| 1631018 | S-valve |

| 1631023 | S-valve |

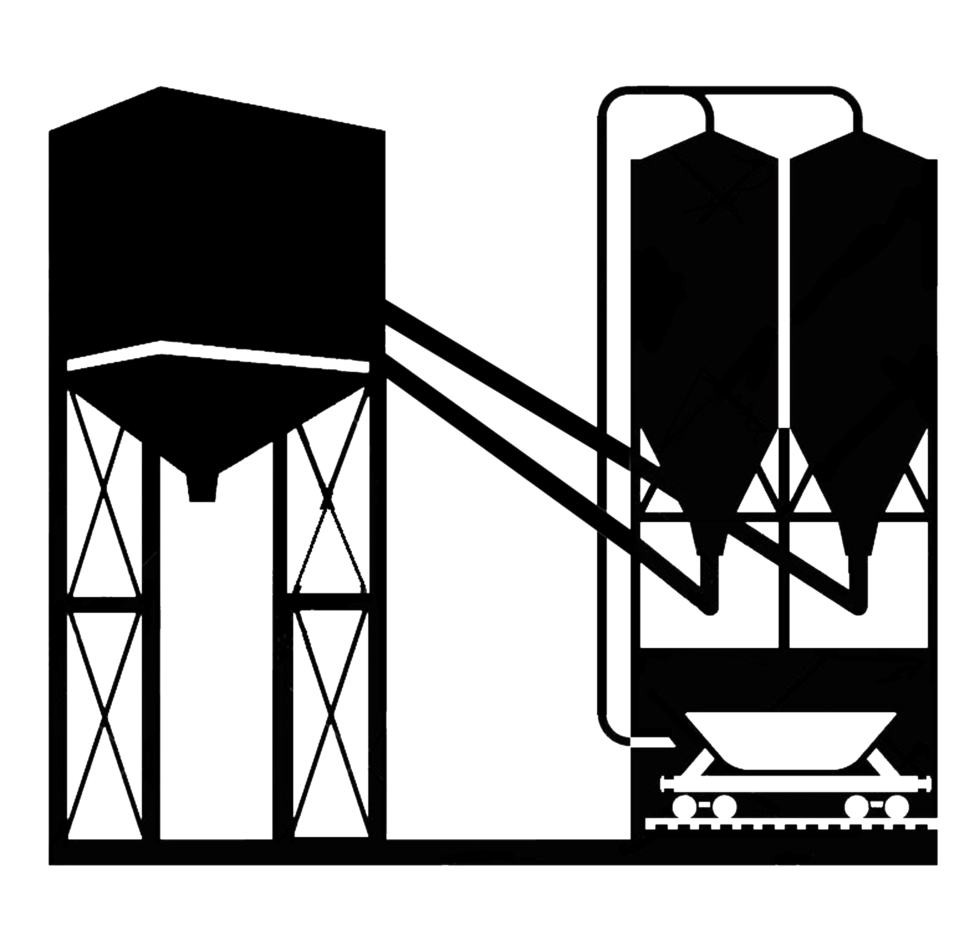

Delivery barrel

Concrete delivery barrels, together with the pistons, pump the concrete from the pump hopper to the distribution pipeline. RM® produces steel barrels with internal chrome plating of constant thickness along the entire length to be compatible with the major pump manufacturers in the market. On specific requests from customers, RM® is able to produce delivery barrels according to drawings.

| Part Number | Description | Dimensions |

|---|---|---|

| 1151028 | chromed delivery barrel | 180×1097 |

| 1151024 | chromed delivery barrel | 230×2164 |

Rubber piston

The pistons, together with the chrome delivery barrel and the S-valve, are the heart of the machine. RM® produces rubber pistons with a compound capable of withstanding the heaviest duties to which they are subjected. The pistons are made using both the classic technology based on metal cores (generally made of cast iron or steel) on which the rubber is vulcanized, and the more recent technology that involves the use of replaceable caps and guide seals, fixed on supports generally made of aluminium alloys. In the latter case, in compliance with the different design choices, the lightness of the assemblies (about 20% less) can be achieved, which is particularly advantageous for the life of the system. We have pistons compatible with the most common brands in the market.

| Code | Description |

|---|---|

| 1421041V | piston DN180 |

| 1421033V | piston DN230 |

Hopper mixing blade

RM® manufactures concrete mixing paddles made of high wear resistant cast iron, for the majority of machine brands on the market. These paddles are installed in the feeding hoppers of concrete pumps and truck-mixer pumps.

| Part number | Description |

|---|---|

| 1381007 | blade for hopper mixer |

| 1381008 | blade for hopper mixer |

| 1381009 | blade for hopper mixer |

Sermac® is registered trademark. RM® is an independent manufacturer and not related to the mentioned company. Trademarks, symbols, codes and manufacturer descriptions are for reference purposes only.