MP SERIES

The vertical axis BASE® planetary mixer (MP series) is made with an external structure in standard steel internally coated with replaceable parts made of wear-resistant steel. The mixing of the product takes place by means of carpentry arms and hardened steel blades. The movement of the mixing parts is ensured by an electric motor combined with a reducer and torque divider acting on the mixing arms. The perfect homogeneity of the mixture is ensured by a large-diameter tank in order to have a lower layer of mixture and therefore easier handling. The large radius unloading door and the additional accelerating unloading blade allow a more rapid emptying of the mixing tank compared to the current versions on the market. The remarkable simplicity of the secondary reduction unit together with the use of a commercial type primary reduction unit allows for quick maintenance operations and extremely high operational reliability. The mixer can be supplied with all the equipment required by modern Prefabrication and Ready Mix technology. In road gauge in every set-up.

Vertical axis BASE® planetary mixers (MP series) are used in concrete plants to produce certified products with high performance, mainly for the production of ready-mixed, precast or pre-compressed concrete, cementitious products, dry premixed products but also in other sectors such as glass, refractories for foundries and chemical products.

- Reliability over time

- Low maintenance costs

- Easy cleaning operations

INSPECTION DOOR

Cover with inspection door and protection net. Safety devices according to accident prevention regulations.

| TECHNICAL DATA | MP | 525/350 | 600/400 | 750/500 | 1125/750 | 1500/1000 | 1875/1250 | 2250/1500 | 3000/2000 |

|---|---|---|---|---|---|---|---|---|---|

| Dry filling capacity (aggregates+cement) | lt | 525 | 600 | 750 | 1125 | 1500 | 1875 | 2250 | 3000 |

| Compacted concrete per batch | lt | 350 | 400 | 500 | 750 | 1000 | 1250 | 1500 | 2000 |

| Mixer drive | nr. | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Power | kw | 11 | 15 | 18.5 | 30 | 45 | 55 | 55 | 90 |

| Star- Delta connection | - | - | - | - | - | - | - | - | - |

| Power frequency | Hz | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 |

| Mixing stars | nr. | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 |

| Planetary mixing blades | nr. | 3 | 3 | 3 | 3 | 2+2 | 2+2 | 2+2 | 2+2 |

| Lateral scraper blade | nr. | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 2 |

| Discharge speeding up blade | nr. | - | - | - | - | 1 | 1 | 1 | - |

| Hydraulic operated discharging door | nr. | 1/2/3/4 | 1/2/3/4 | 1/2/3/4 | 1/2/3/4 | 1/2/3/4 | 1/2/3/4 | 1/2/3/4 | 1/2/3/4 |

| Motor power for hydraulic system | kw | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 2.2 |

| Mixer weight without Skip | kg | 1400 | 1900 | 2400 | 3500 | 4800 | 5100 | 6100 | 8500 |

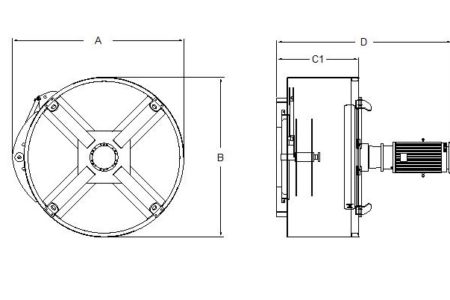

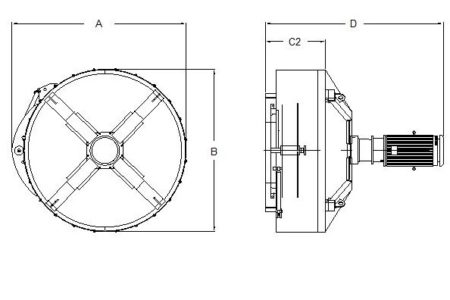

| MP SERIES | |||||

|---|---|---|---|---|---|

| Dimensions | |||||

| Code | A | B | C1 | C2 | D |

| BSMP525/350 | 1660 | 1500 | 1207 | 862 | 2100 |

| BSMP600/400 | 1600 | 1500 | 1207 | 862 | 2150 |

| BSMP750/500 | 2010 | 1850 | 1207 | 862 | 2200 |

| BSMP1125/750 | 2460 | 2290 | 1194 | 885 | 2470 |

| BSMP1500/1000 | 2650 | 2470 | 1280 | 913 | 2632 |

| BSMP1875/1250 | 2650 | 2470 | 1280 | 913 | 2593 |

| BSMP2250/1500 | 2930 | 2750 | 1307 | 970 | 2756 |

| BSMP3000/2000 | 3170 | 2950 | 1400 | 1000 | 3092 |