Our STAR filters are made with a cylindrical main body in stainless steel with a flanged ring in the lower part. The upper part consists of a cover made of plastic material that can be opened, the support plate for the filter cartridges is made of painted steel while the cleaning system consists of a lung with integrated solenoid valves in aluminium and firing tubes in plastic material. The rectangular-shaped filter cartridges are made of synthetic material. The welded flange for coupling to the silo, supplied separately, is made of anti-rust treated steel. The electrical panel for filter management, which can be supplied with multi-voltage (24-115-230 volts ± 15%, 50-60Hz), can be of the classic sequencer type or with a digital pressure switch; in the first case, the cleaning phase of the filtering cavities is managed manually by the operator by switching the panel on and off, while in the second case, cleaning takes place automatically by continuously checking the efficiency of the filtering cavities. The pressure switch gives the possibility to visualize the internal pressure of the filter and then of the silo on a special display and can interact with the latest integrated safety systems.

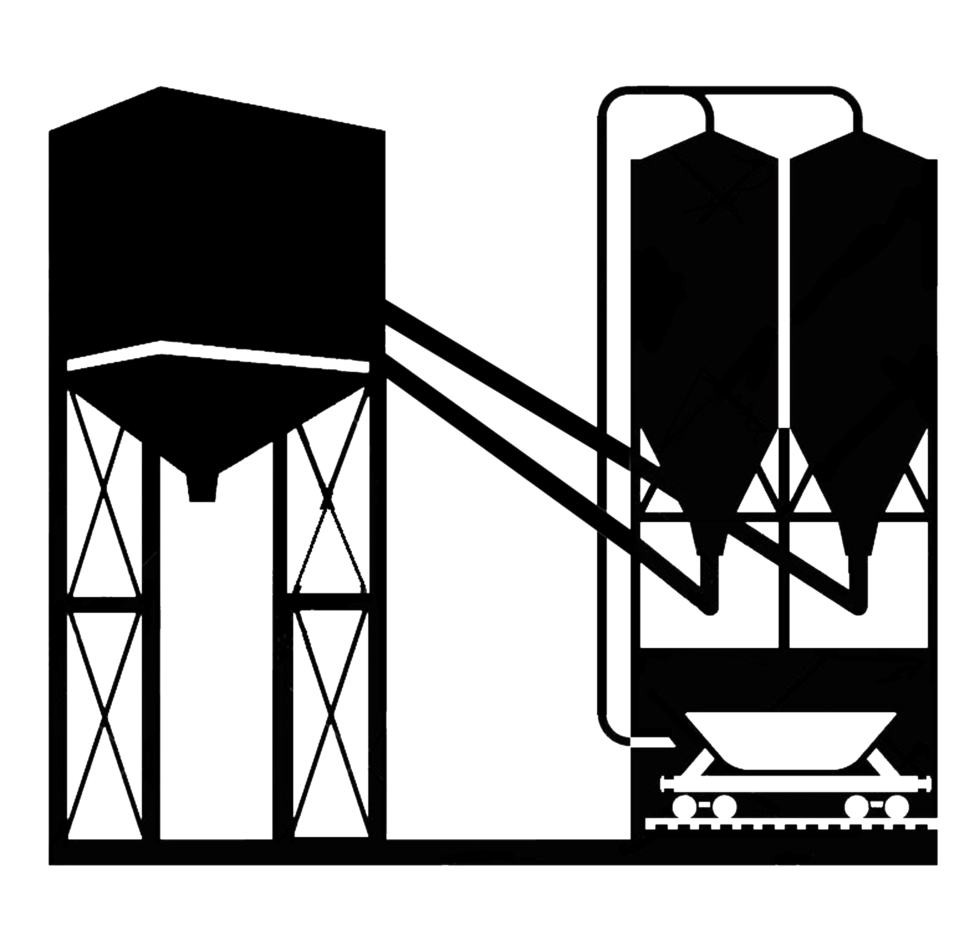

USAGE

STAR filters are normally installed on silos in concrete production plants. Their main function is to retain the cement powders that are generated inside the silo during the loading phase to prevent them from being dispersed into the atmosphere. In addition, they ensure the entry of air into the silo during the production phases in the plant. STAR filters are available in different versions according to the customer’s needs: square meters of filtration 24,5 or 14, management of the cleaning phases of the filtering cavities using a panel with pressure switch or with a simple sequencer panel.

BENEFITS

- Ease of installation

- Compact size product

- Low maintenance costs

- Reliability over time

| Code | Description |

|---|---|

| BSFSTR7/24 | STAR Filter with multitension board 24/220 volt 50 Hz sequencer |

| BSFSTR7/24-QP | STAR PLUS Filter with multitension board 24/220 volt 50 Hz sequencer and pressure switch |

| Technical Data | |

|---|---|

| Filtering Surface | 24.5 mq |

| Cartridge | 7 |

| DN Filter | 808 |

| Body Filter | Stainless steel |

| Height Filter – Flange Excluded | 1100 |

| Numbers Electrovalves | 3 |

| Packaging Dimensions | 1050x1000x1300 |

| Gross Weight | kg 79 |

Cleaning system

The air jet cleaning unit is completely integrated inside the weather protection cover. Dust is separated from the air flow by the filter elements and it dops back into the silo after its removal from the filter elements.

Multitension board

Multitension board 24/220 volt 50 Hz with differential pressure switch, display and adjustable alarm threshold.

| Code | Description |

|---|---|

| BS202.006 | Sequencer and pressure switch board |

| BS202.005 | Sequencer board |

Solenoid Valve

| Code | Description |

|---|---|

| BSKEVN02450 | solenoid valve (nr. 3 per filter) |

Cartridges

| Code | Description |

|---|---|

| BS20647794A | Cartridge for STAR Filter |

Flange

| Code | Description |

|---|---|

| BSFF770 | Flange to fix the filter on the silo |

| Code | Description |

|---|---|

| BSFSTR4/14-Q | STAR Filter 14 mq with multitension board sequencer |

| Technical Data | |

|---|---|

| Filtering Surface | 14 mq |

| Cartridge | 4 |

| DN Filter | 808 |

| Body Filter | Stainless steel |

| Height Filter – Flange Excluded | 1100 |

| Numbers Electrovalves | 2 |

| Packaging Dimensions | 1050x1000x1300 |

| Gross Weight | kg 70 |

Cleaning system

The air jet cleaning unit is completely integrated inside the weather protection cover. Dust is separated from the air flow by the filter elements and it dops back into the silo after its removal from the filter elements.

Multitension board

Multitension board 24/220 volt 50 Hz with differential pressure switch, display and adjustable alarm threshold.

| Code | Description |

|---|---|

| BS202.005 | Sequencer board |

Solenoid Valve

| Code | Description |

|---|---|

| BSKEVN02450 | solenoid valve (nr.2 per filter) |

Cartridges

| Code | Description |

|---|---|

| BS20647794A | Cartridge for STAR Filter |

Flange

| Code | Description |

|---|---|

| BSFF770 | Flange to fix the filter on the silo |